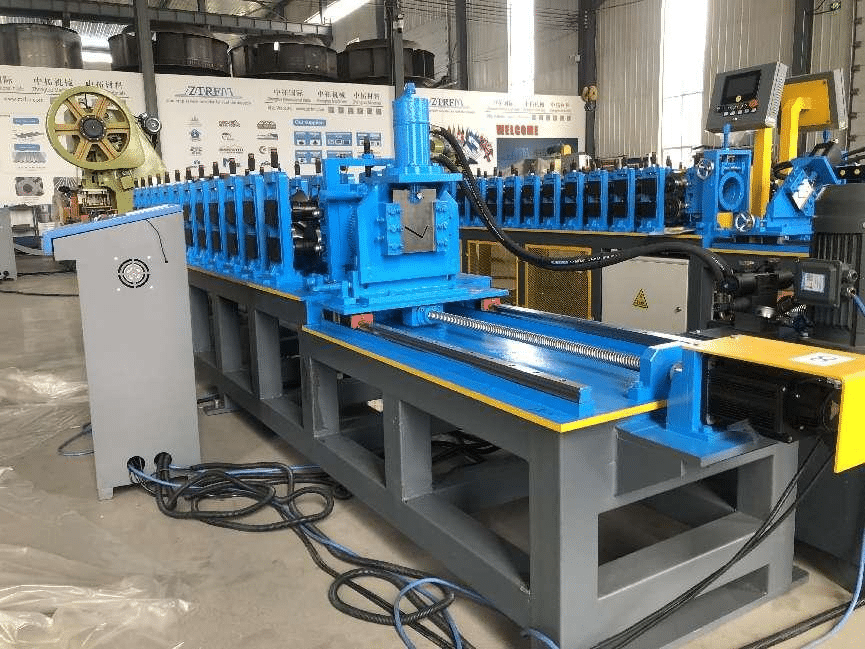

The Steel Stud Drywall Framing System offers a robust, practical, and lightweight solution for interior gypsum board walls as well as certain exterior walls. The metal profile components for partition systems, including Studs, Tracks, C-Channels, Corner Beads, and accessories, are crafted from hot-dip galvanized steel. The CW UW frame roll forming machine is equipped with a CNC control system, ensuring fully automated operation of the steel framing roll former for C studs and tracks. The cutting device on the steel framing roll former utilizes a high-speed servo motor cutting system. This machine is capable of producing C studs and U tracks for suspended ceiling systems and drywall steel framing systems. Features such as a punching hole device, logo punching device, high-speed flying saw cutting device, and an automatic receiving table system can be incorporated into the design for C studs and U tracks.

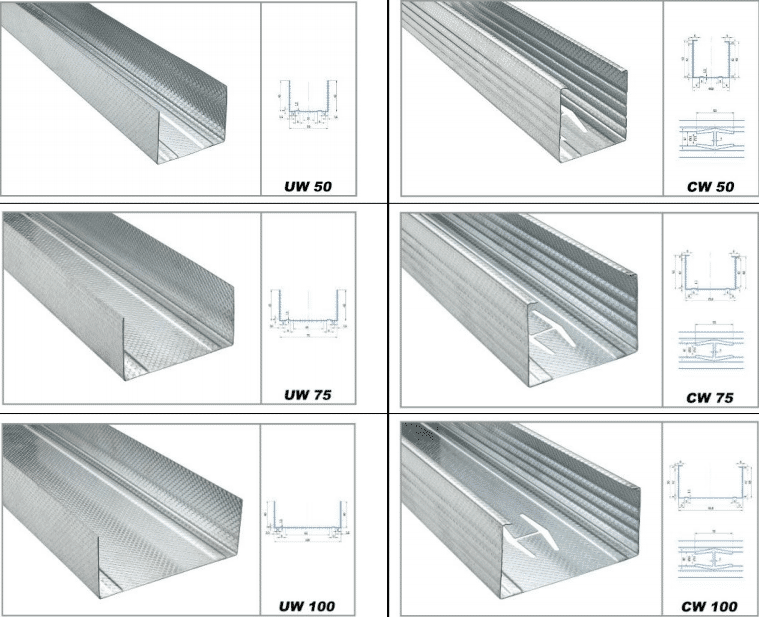

Here is a drawing profile and the finished product: Product Details:

For enhanced control over lateral deflection and axial rotation at the head of the wall, ZTRFM’s Rapid Track slotted deflection track provides an effective solution for interior and exterior walls that bear significant weight loads or are exposed to dynamic wind forces.

Rapid Track enables the top of the steel stud wall to float within the track’s legs, accommodating vertical live load movement of the primary structure without imparting axial loads to the wall studs.

Moreover, Rapid Track features slots in the track to permit horizontal drift as necessitated by seismic design requirements.

Available in 3000mm leg lengths and a range of track widths from 64mm to 150mm, Rapid Track is straightforward to install and helps to reduce the cost of materials and labor.