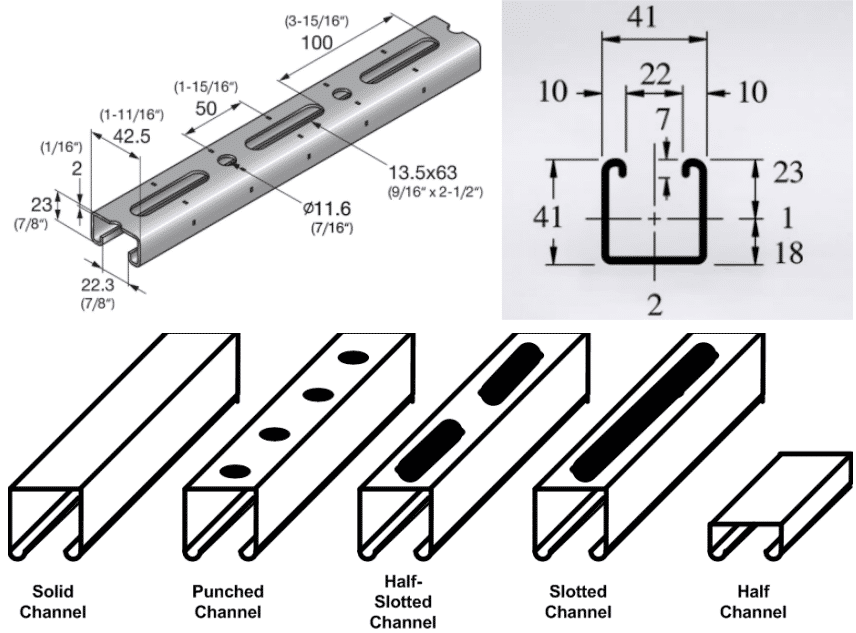

Steel Slotted Strut Channel Rolling Forming Machine

he Steel Slotted Strut Channel Rolling Forming Machine is engineered for the mass production of strut channels in a fully automated process. Typically utilized as a standard structural element for supporting electrical or plumbing fixtures like cable trays, lighting rigs, or pipe clamps, this versatile product also finds application in a variety of other installation scenarios. The machine produces 41mm slotted channels with pre-punched holes, ideal for use in outdoor settings and made from galvanized steel.Here is the one drawing profile for your reference:

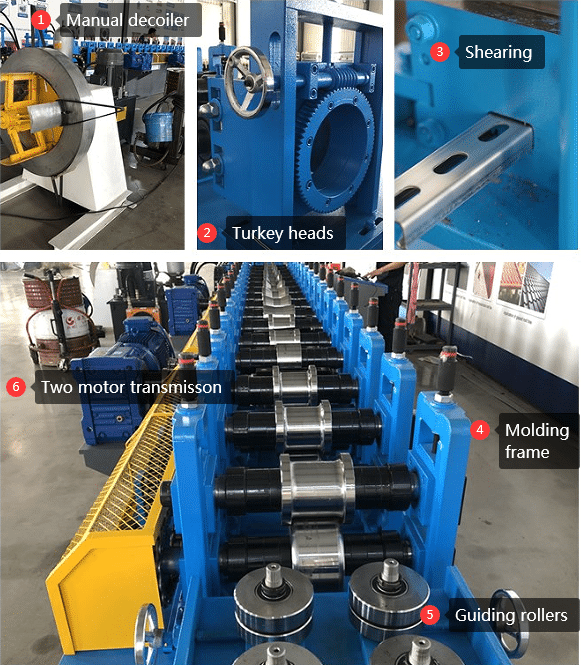

The system is comprised of several integral components: a 3 Ton decoiler, a primary rolling forming machine equipped with a servo-driven punching mechanism and a shearing system, as well as a receiving table.

Benefits of the light duty strut channel rolling forming machine include:

1. The decoiler is available in either a hydraulic automatic version or a manual option. The manual version still includes a safety arm to prevent coil peeling and a brake for added security.

2. The main rolling forming machine features a durable molding frame designed for extended use and solid construction.

3. The rolling section includes two specialized heads: one with tape rollers to ensure the sides are straight, and another to maintain straightness along the length.

4. For the punching process, we employ a servo motor for inline punching. This setup can punch 10 holes in a single pass and repeats the action 40 times per minute, achieving a production speed of 20 meters per minute.

5. The punching design is configured to punch from the bottom up, which guarantees a smooth surface finish.

6. The hydraulic station is equipped with an energy tank, enabling continuous shearing and punching operations without interruption.