T-bar forming machines are sophisticated pieces of equipment designed for manufacturing suspension systems for drop and suspended ceilings. Commonly used in commercial and industrial facilities, these systems create a finished ceiling look that hides mechanical elements while maintaining an attractive appearance.

The primary T-bar is an essential horizontal element that extends across the room, providing the main support for the ceiling grid. Typically constructed from metals like galvanized steel, it is engineered to support the full weight of the ceiling system.

Advantages:

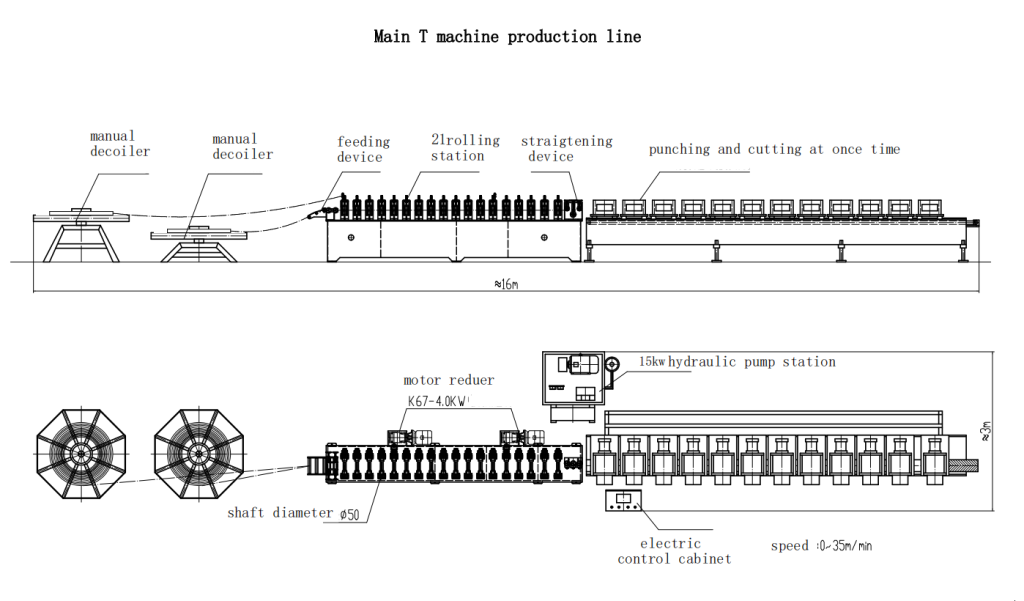

1. Our ceiling system machine combines punching and cutting functions, completing both tasks in a single operation.

2. The main T-bar can be cut to a length of 3.6 meters, with one piece produced per cycle. For the cross T-bar, lengths of 0.6 meters or 1.2 meters are available, yielding either two 0.6-meter pieces or one 1.2-meter piece per cycle.

3. The machine operates at high speeds, with the main T-bar forming machine capable of reaching up to 35 meters per minute and the cross T-bar forming machine up to 25 meters per minute.

4. The versatile machine is capable of producing both flat and black center T-bars. It is equipped with a total of 21 rolling stands, with stands No. 18 and No. 19 specifically used to form the black center groove. By adjusting the gap between the upper and lower rollers, the machine can be configured to produce flat T-bars without the groove when passing through stands No. 18 and No. 19.