Drywall and Ceiling Double Line Roll Forming Machine

A drywall and ceiling double line roll forming machine is a specialized piece of equipment used in the construction industry for the automated production of drywall and ceiling profiles. This machine is designed to manufacture metal profiles that are commonly used in the construction of walls and ceilings, particularly for partition walls and suspended ceilings.

Advantages

1. High Production Efficiency: This machine is specifically designed for continuous forming and cutting of drywall and ceilings, enabling efficient production, increased production speed, and output.

2. Versatility: One machine can accommodate different specifications and types of drywall and ceilings, enhancing production flexibility and diversity.

3. Precision and Consistency: The machine ensures consistent product dimensions and shapes, improving product quality and reducing waste.

4. Reliability and Durability: These machines typically use high-quality materials and manufacturing processes, providing durability and stability, reducing equipment failures, and minimizing downtime.

5. Labor Cost Savings: Automation and efficient production processes reduce dependency on labor, thereby lowering labor costs.

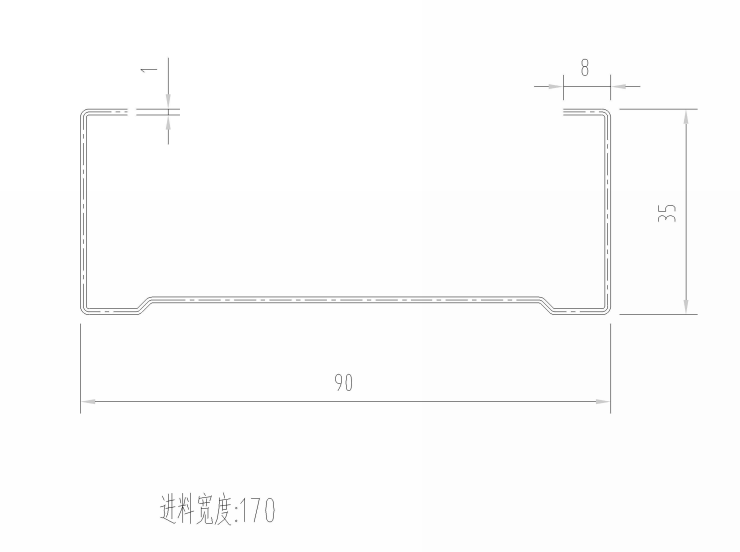

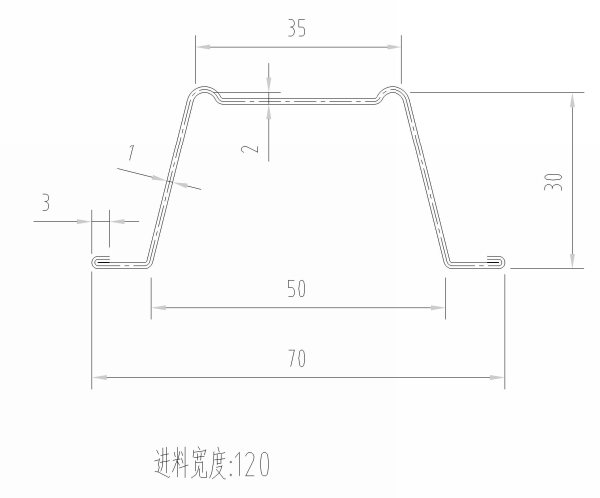

Profile drawing for reference:

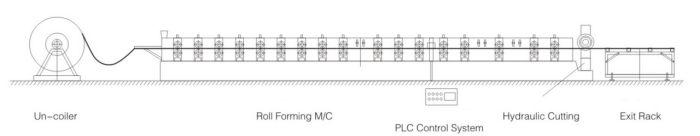

Working flow:

Decoiler—–feeding device—roll forming machine—cutting part—products receiving table

| Technical Parameters | |

| Raw material of the coil | Galvanized steel |

| Cutting length | adjustable |

| Work voltage | 380V, 50Hz, 3Phase (as your requirement) |

| Work speed | 40m/min |

1: double head manual decoiler

1. Work type Passive type

2. Structure Steel channel welded for basic frame

3. Usage To support the coil and make the uncoiling

4. Loading capacity 1.5 tons

5. Inner diameter 450-550mm (manual adjustment)

6. Brake system Manual brake

2: main roll forming machine

1. Feeding device: One set guiding roller

2. Rolling shaft: 45# Shaft diameter: 50mm (The shafts we use are all solid shafts.The shaft by sawing, quenching and tempering, lathes, cylindrical grinders and milling machines, and other process. )

3. Roller: 45#, with hard chromed, quenched (Rollar process flow through the roll raw material through forging, machine tool processing, quenching to 58°–62°, secondary machine tool processing, milling keyway processing, polishing, electroplating hard chromium treatment, and finally processed into a roll. The roller produced by this process has high smoothness, and the products produced are more smooth, high hardness, more rust resistant, longer service life and more beautiful.)

4. Work speed: 40m/min

5. Roller station: 11 station + 11 station

6. Machine structure: Arch structure (More strengthening and produce more neat production)

7. Machine basic frame: Steel plate welded

8. Work power: 5.5kw + 5.5kw

9. Drive mode: by chains

10. Punching logo: 1 punching unit + 1 punching unit

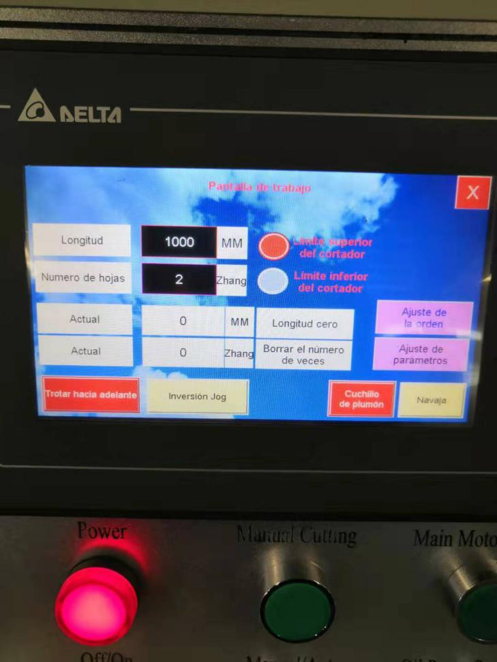

3: PLC control station

1. Frequency brand: Delta brand (original)

The touch screen is Delta, easy to operate, high in accuracy, and can design various parameters and functions.

The control button is Schneider.

If there is no touch screen, then if a button is broken, then no PLC can be used. The electronic contacts in our buttons are made of silver, which has better conductivity, accuracy and long service life.

2. Screen type: Touch screen,also have bottons on the panel

3. Screen language: English / Chinese(The default language of the panel is Chinese/English, it can also be customized into other languages according to customers’ needs.)

4. Cut command: Yes

5. Profile length set-up: Yes

6. Bacth quantity program: Yes

7. Low pressure electric part: Schneider brand

If you are afraid of machine problems and the distance is too far, you can add the remote operating system of plc when purchasing the machine. If there is a system problem with this machine, you can contact our engineers to debug it for you remotely from China.

4: Hydraulic station

1. With cooling fan or not: Yes

2. Hydraulic motor power: 3.0 kw

3. Hydraulic oil: 46# oil

4. Oil tube and wires connection: All the tubes and wires will be marked by the numbers or letters, so that it will be very easy to connect for the new

The motor of hydraulic station is a Chinese standard brand with good quality and long service life, which can reach more than ten years. Since the establishment of our company, no customer has ever reported that the motor is damaged. It seems that the cost of the motor is very low, but if other motors with poor quality are used, once they are damaged, the accessories are very small, but the postage is very expensive, and you have to wait for the mailing time, which will delay your work.

5: Cutting system

1. Work type: Servo hydraulic cutting

2. Cutter material: Cr12

6: Counter

The counter adopts Omron counter, which has accurate counting measurement and long service life.

7: Product receiving table

Table length: 3m

Material: Square tube welded