Drywall CU channel roll forming machine

Drywall CU channel roll forming machine is widely used in the ceiling and drywall construction. Compared with cement construction and wooden construction, steel frame is more light and durable. Thanks to these advantages, C/U/Omega stud is welcomed in construction field.

Why use this Drywall CU channel roll forming machine?

1. Dry operation, safety, construction, and self-destructive division space, it is easy to remove. Can save manually, speed up the construction speed.

2. Light weight and strength can meet the needs of use. It is a very good partition with two light gypsum boards.

3. Chemical physical properties are stable, dry moisture absorbing gas, small telescopic deformation

4. Decorative effect. The surface layer of the gypsum board can be compatible with a variety of surface layer decorative materials to meet the decoration requirements for large-scale buildings.

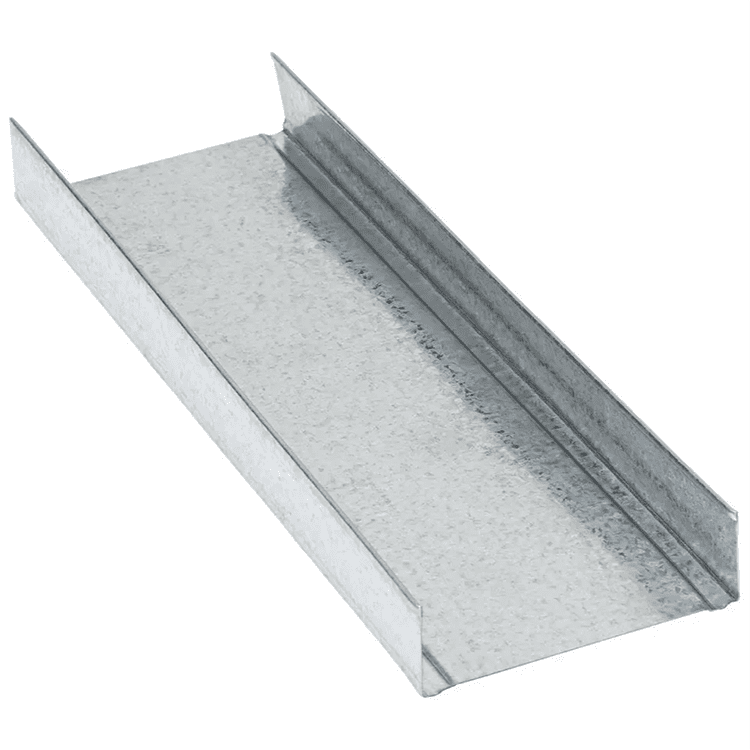

The pictures for the finished product:

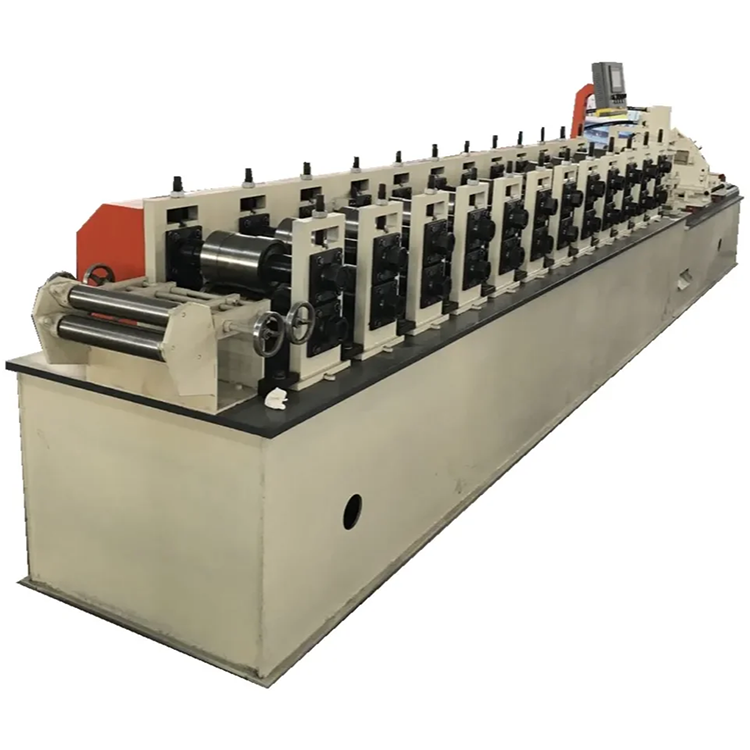

Technical parameters

Formed Material: GI

Thickness: 0.5-0.7mm

Roller station: 12 rows(As your requirement)

Diameter of shaft: 50 mm solid shaft

Material of rollers: 45# steel, hard chrome plated on the surface

Machine body frame: Metal steel welded

Drive: Gearbox transmission

Cutter: Cr12mov material, no scratches, no deformation

Motor Power: 7.5KW

Hydraulic system power: 5.5 KW

Voltage: 380V 50Hz 3Phase(As your requirement)

Control system: PLC

Forming Speed: 40-45m/min(customized)

1.Manual Decoiler

1. Work type: Passive type

2. Loading capacity: 3 Tons

3. Coil inner diameter: 450-550 mm (adjustable)

4. Quantity: 1 set

2. Entry Beach

Usage: Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity.

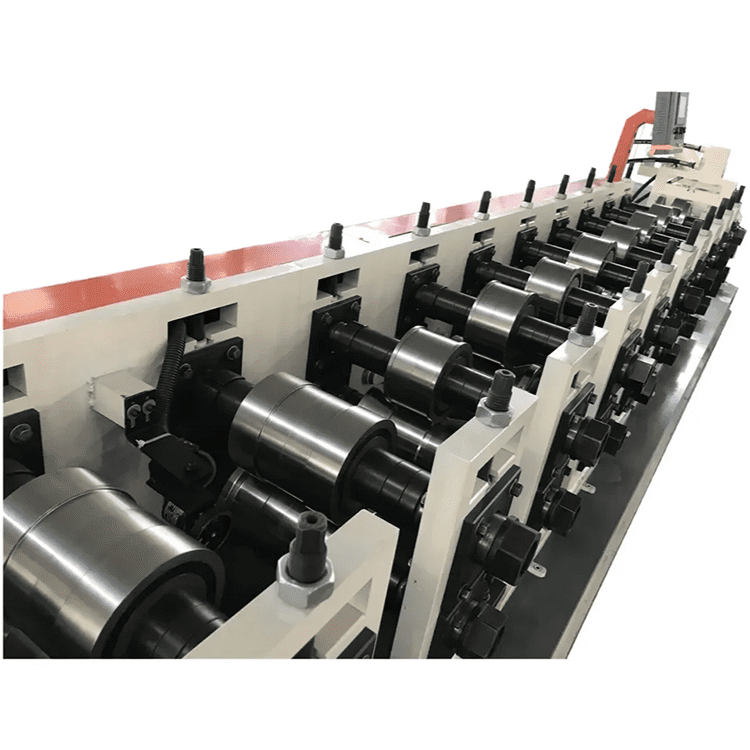

3. Roll Forming System of drywall system machine

1. Feature: The one side machine frame can be move by PLC control to adjust the stud and truck dimension.

2. Machine frame: Vertical iron arch casting frame structure

3. Bearing: Chinese famous brand Harbin

4. Hydraulic System

1. Work type: Hydraulic track cutting with servo motor

2. Driving method: By pillar type Cylinder

3. Cutter material: GB-Cr12

4. Cutting length tolerance: ±1 mm/3 m

5. Cutting feature: Automatic

cutting after forming, no distorting.

5.Hydraulic station

1. We weld the hydraulic station with the machine, so you do not need to connect lots of pipes and wires. So it is easy for installation.

2. With cooling system, it can make sure shearing powerful even if in hot weather.

6. PLC control system

1. PLC brand: Delta(Taiwan)

2. Frequency converter brand: Delta(Taiwan)

3. Encoder: Omron

4. Function: Automatic control the length,quantity and batch