Top Hat Furring Channel Light Gauge Steel Machine

Advantages:

1. The furring channel making machine is stable, no noise, no shake.

2. Controlling by computer, PLC display, operation is easy, running is steady and reliable, endurable.

3. Cutting machine is characterized by stable driving, easy operation.

4. Hydraulic system use the hydraulic pump, long operating life, no noise.

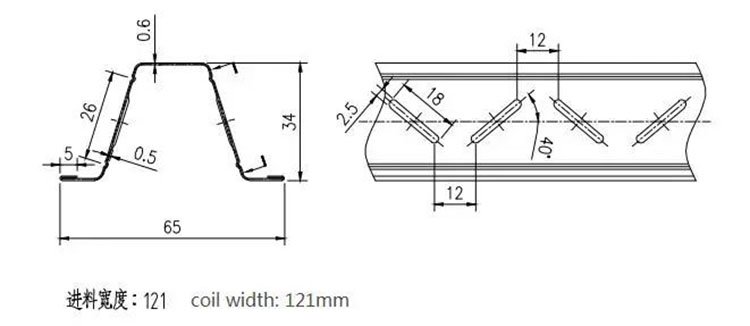

Profile drawing for reference:

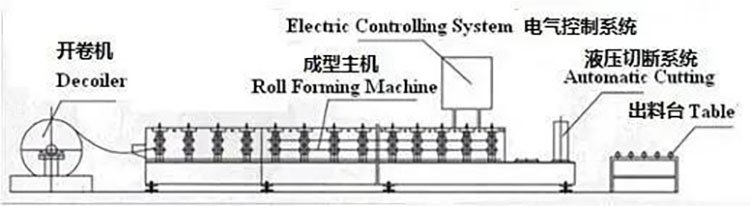

Working flow of cold roll forming machine:

Decoiler– Roll Forming–PLC System—Hydraulic System –Cutting Output Table

Technical parameters

Voltage: 380V 50HZ 3Phase or as you need

Frame: 400 H steel or as you need

Drive mode: gear

Main axle material: GR15

Material of shafts: 45# steel

Diameter of shafts: φ50 -φ80mm

Number of rollers: 11 rollers

Main power: 7.5-11kw

Forming speed: 8m-30m/min

Adjustment method: Half seams type Looper

1.Hydraulic decoiler

1. Loading capacity: 1.5T

2. Uncoiling width: 300mm

3. Inner diameter: 450-550mm

4. Has power, it can work automatically

5. Automatically adjust the decoiler to fit into the coil accorind to the coil diameter.

2.Feeding Part

Four stainless rollers can make the material go into the hat furring channel roll forming machine smoothly and prevent the scratch on the material surface.

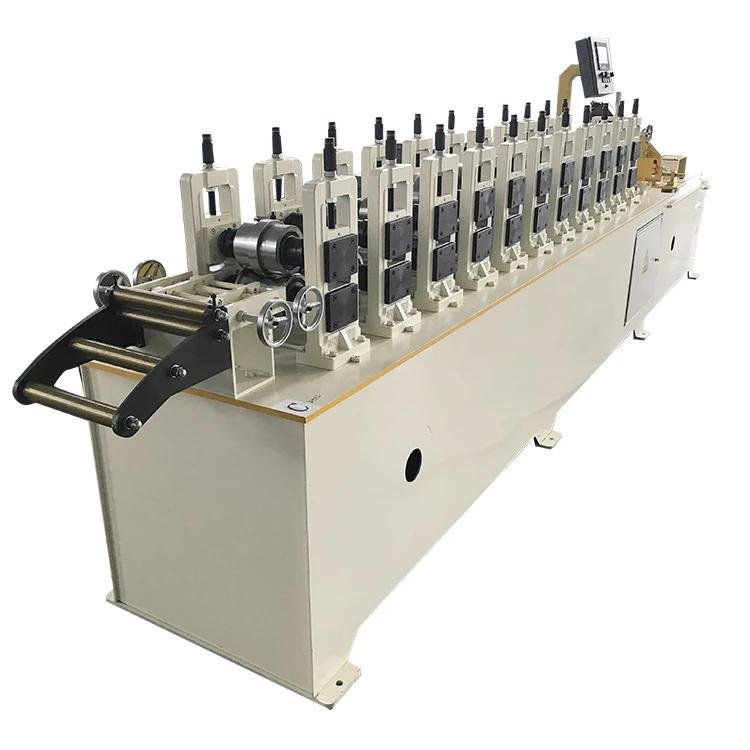

3. Roll forming machine

1. Voltage: 380V/50HZ 3Phase (as customer’s request)

2. Roller fixer: Guide column

3. Frame: middle plate welded

4. Frame thickness: 25mm

5. Drive mode: gear

6. Material of rollers: GCr12MoV

7. Material of shafts: 45# steel with tempering

8. Diameter of shafts: φ40mm

9. Number of rollers: 11rollers

4.Shearing machine

Together with punching words, cutting will be done together.

1. Material of blades: Gcr12 quenched

2. Power supply: hydraulic power

3. Frame: Pillar style with rack & pinion system

4. Stroke switch: non-contact photoelectric switch

5. Hydraulic Station

1. Hydraulic motor Power: 3kw

2. Hydraulic oil: 46#

3. Components: The system includes a set of hydraulic tank, a set of hydraulic oil pump, and two hydraulic pipes. And three sets of electromagnetism valves.

6.Electric Control System

1. Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

2.Other electric element are Delta.

3. Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety.