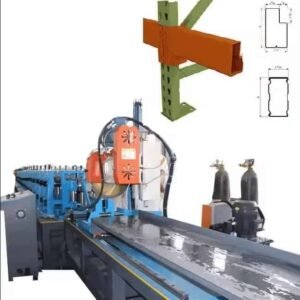

Heavy duty Z beam shelf roll forming machine

A heavy-duty Z beam shelf roll forming machine is a specialized piece of equipment designed for manufacturing Z-shaped beams or channels commonly used as shelves in storage racks or shelving systems. These machines efficiently produce Z-shaped profiles from coil metal sheets.

Sturdy shelves, alternatively referred to as crossbeam shelves or cargo space shelves, fall under the pallet shelf category and represent the prevalent type of shelves in diverse international storage systems. The streamlined and efficient design consists of fully assembled column pieces and beams. Depending on the features of the storage unit packaging equipment, additional functional elements such as partitions, steel layers (steel grating), metal mesh layers, storage cage guide rails, and oil barrel racks can be incorporated. This flexibility allows for the fulfillment of varying storage needs for goods in different forms of unit packaging equipment.

Key features and advantages of Z beam shelf roll forming machine:

1. Efficient Forming Process: Utilizes an efficient roll forming process to quickly shape metal coils into Z-shaped beam profiles, enhancing production efficiency.

2. Suitable for Heavy-Duty Materials: Specifically designed to work with heavy-duty metals such as steel, ensuring the produced Z-shaped beams possess sufficient strength and load-bearing capacity for industrial applications.

3. Versatile Design: Adjustable to accommodate various sizes and thicknesses of metal coils, providing flexibility in production to meet different specifications of shelves.

4. Precision Cutting: Equipped with a precise cutting mechanism to ensure uniform length of the produced Z-shaped beams, meeting specific customer requirements.

5. Modern Control System: Features an advanced control system for easy operation and precise adjustment of parameters such as speed, length, and thickness, ensuring stability and accuracy in the manufacturing process.

6. High Production Speed: Designed for high-speed production to quickly meet the manufacturing demands of large quantities of shelves, improving overall production efficiency.

7. Quality Control Mechanisms: Integrated quality control mechanisms and sensors to ensure that the produced Z-shaped beams meet industry standards, delivering high-quality end products.

8. Safety Design: Designed with safety features, including emergency stop buttons and protective guards, to ensure the safety of operators during the production process.

9. Optional Post-Processing Features: Depending on customer requirements, the machine may offer additional post-processing options, such as hole punching, embossing, or customized surface treatments.

Heavy-duty z beam shelf roll forming machine profile drawing and working flow:

Heavy-duty z beam shelf roll forming machine technical parameters:

1. Pressure roller material: stainless steel

2. Feeding width adjustment : Manual

3. Main roll forming machine

4. Roller material: GCr12 Quenching

5. Frame type Molding frame

6. Material of shafts 45# steel with tempering

7. Diameter of shafts Φ70mm

8. Number of rollers 16 rows of roller station

9. Main motor power 11 kw + 11 kw

10. Material thickness 2.5mm

11. Forming speed 0-15 m per minute

1. 3T hydraulic Decolier

Capacity:5 tons

Coil inner diameter:450-550mm

Feeding width: max 300mm

Structure: welded by the steel plates and profiled bar.

The shrink and expand of coil is automatic , Drive by Electric power.

2. Feeding

Feeding roller material : stainless steel

3. Roll Forming And Transmission Device

Rollers material: Cr12 quenching

Roller stations: 18rows

Shaft material:Shaft material: 45# steel with finishing processing

Heavy duty chains: 1.2 inch

4. Hydraulic Cutting Device

Material of blade: Cr12mov quench treatment

Length measuring: automatic encoder measuring,Tolerance of length is 3000mm+- 1.0mm