Follow these steps to perform a remote acceptance of the Quick Changeover C/U Drywall Stud Roll Forming Machine, ensuring all key aspects are covered through video and photo documentation:

1. General Overview of the Line and Units

- Video: Capture a general view of the entire production line and all units included in the delivery set. Ensure all parts are visible for a comprehensive overview.

2. Measure the Thickness of the Raw Material

- Video: Demonstrate the measurement of the thickness of the raw material metal (coil metal) using a micrometer. Ensure the measurement process is clearly visible.

3. Production of Profile No. 1

- Video: Record the production of 10 pieces of Profile No. 1, each with a length of 3 meters.

- Ensure that the footage is powerful enough to calculate productivity (50-60 meters per minute).

- The video should be taken from the guillotine side, clearly showing how the guillotine cuts the profile.

- Without interrupting the video, measure the profile’s length and film the profile from multiple sides.

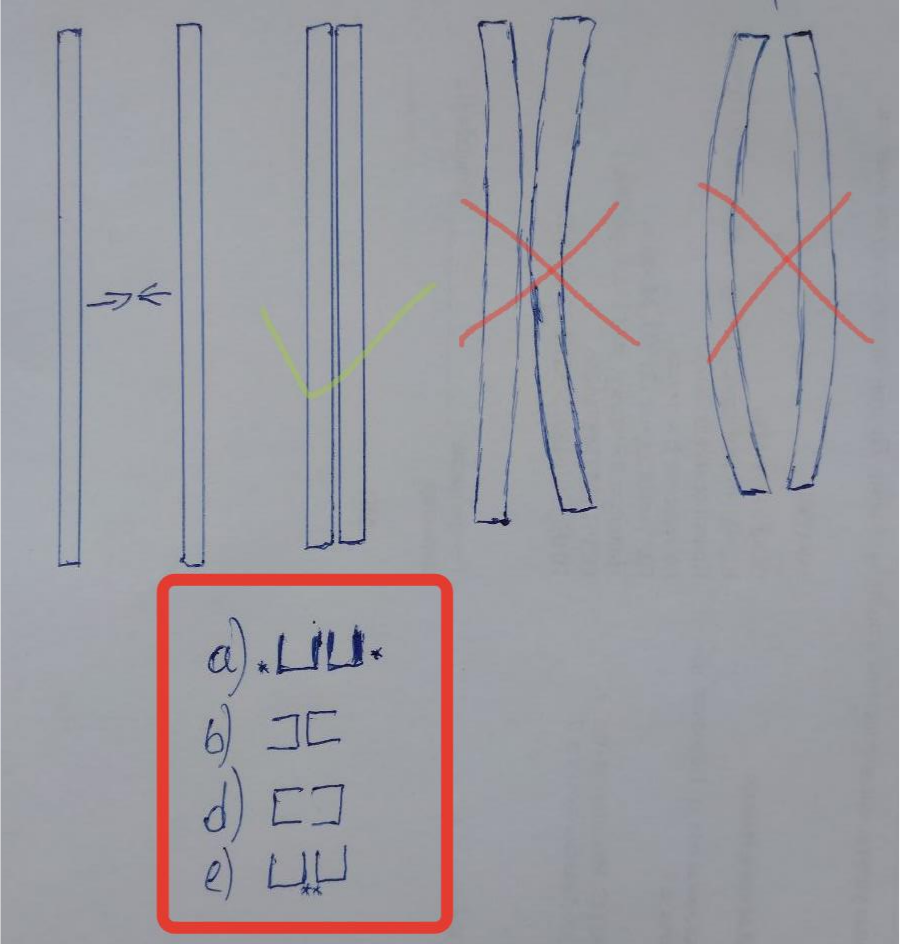

4. Check the Straightness of the Profile

- Video: Take two pieces of the profile and place them tightly side by side, as shown in the provided figure.

- Important: The profiles must not be turned over and should remain exactly as they came out of the machine.

- Capture photos and videos of the profiles in all four positions: a, b, d, e.

5. Check the Quality of the Cut

- Photos: Ensure the cut edges are smooth, with no burrs that can be felt on the fingers.

- Take multiple close-up photos of the profile ends to verify the quality of the cut.

6. Display the Control Panel’s Russian Interface

- Video: Show the Russian-language interface on the control panel, ensuring that the screen is clear and legible for review.

7. Capture Photos of the Control Cabinet Interior

- Take a clear photo of the inside of the control cabinet, showing the components and wiring.

8. Photograph the Rolling Mill Motor and Guillotine

- Photos: Take a photo of the rolling mill motor and guillotine, ensuring the motor power tag is visible.

9. Photograph the Hydraulic Station

- Photos: Capture clear photos of the hydraulic station from multiple angles to ensure all components are visible.

10. Video: Retooling for Profile #2

- Video: Show the process of retooling the machine for Profile No. 2. Demonstrate how the cassette is changed and how the guillotine knives are replaced.

- Question: Verify if any settings need to be adjusted on the control panel for Profile No. 2.

11. Repeat Steps 2-5 for Profile #2

- Perform all steps (2-5) again for Profile No. 2, including measuring, checking cut quality, and ensuring profile straightness.

12. Video: Documentation

- Video: Record a video of the documentation that accompanies the machine, ensuring that all relevant documents are clearly shown.