In today’s era of rapid technological advancements driving change in manufacturing, Cangzhou Zhongtuo Cold Roll Forming Machinery Co., Ltd. has shone brightly on the global manufacturing stage with its exceptional technological innovation capabilities. Recently, Zhongtuo successfully won the favor of Canadian customers and secured orders for multiple keel machines, including partition keel machines, ceiling keel machines, and load-bearing keel machines. This international cooperation project fully demonstrates Zhongtuo’s profound technological foundation and extraordinary charm in the field of technology.

The stud and track forming machine produced by Zhongtuo Intelligence have undergone rigorous testing processes and successfully passed multiple authoritative certifications in North America. This achievement means that Canadian customers can directly put these machines into production without the need for additional cumbersome testing and adjustments, thereby significantly shortening the cycle for equipment deployment. Each keel machine is a testament to the cutting-edge technological wisdom of Zhongtuo.

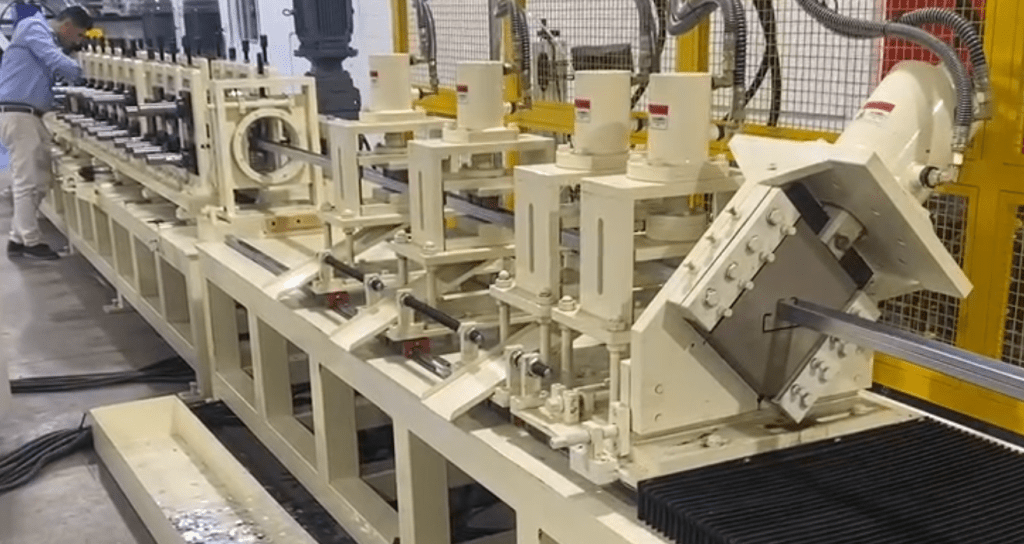

In terms of technological innovation, Zhongtuo’s keel machines showcase multiple leading technologies. The application of the automatic decoiling function achieves automation and efficiency in raw material processing, effectively reducing labor costs and improving production efficiency at the initial stage. At the same time, the introduction of automatic translation and model changing technology gives the equipment high flexibility, enabling it to quickly adapt to different production modes and meet the diverse production needs of keel products.

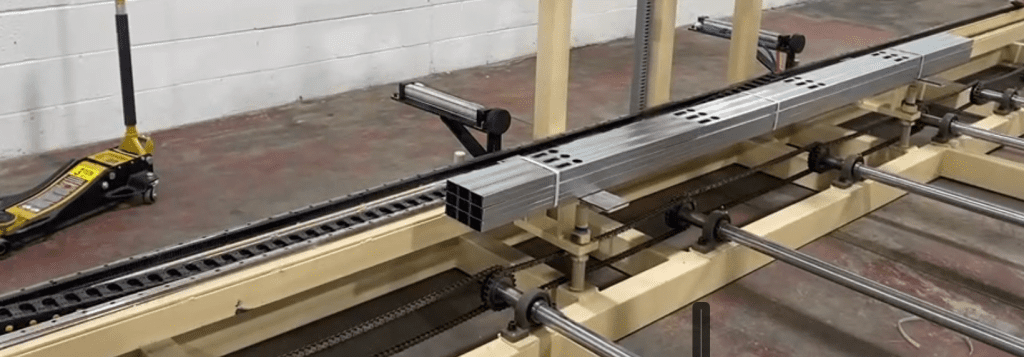

Servo tracking cutting technology is another highlight of Zhongtuo’s keel machines, ensuring precise cutting and enabling each keel to meet strict size requirements, thereby enhancing the overall quality of the products.

In addition, Zhongtuo’s keel machines are equipped with a series of automation functions such as automatic turning and stacking, automatic packaging, automatic conveying, and automatic output. These functions are interconnected, jointly building an efficient and stable unmanned production process. From raw material processing to finished product output, the entire process achieves a high level of automation and intelligence, minimizing human intervention. This not only further reduces labor costs but also significantly improves production stability and product quality, providing a perfect solution for building unmanned factories.